Utilizing Innovative Technology

For Refrigeration Applications Objectives

Current dehumidification systems present in air conditioning systems squander a large amount of energy, while Nanocap’s transformative process avoids this waste by separating the cooling process from dehumidification. In doing so, there is a substantial savings on operating costs, maintenance costs, and certainly a positive environmental impact..

Energy Savings

How much energy does our system actually save?

- Current defrost cycles consume between 10%-30% of refrigeration energy

- Modular system allows scaling based on user conditions

- Helps meet current and anticipated future energy efficiency standards

Environmentally Friendly

- Appropriate humidify levels ensure food freshness over a longer period without spoilage and mold growth

- Food packaging susceptible to humidity levels ensure increased shelf life

- Elimination of stagnant water and frost formation

Lower Operating Cost

- Elimination of defrost cycle reduces component wear and maintenance

- Aids in reduction of food waste due to inadequate cold storage routines

- Draw solution reconcentration can integrate with condenser coils creating a mutually beneficial heat transfer

View Our Press Release To Find Out More

We invite organizations from a variety of industries to experience the advantages of The Nanocap Process for your dehumidification needs

Industries of Interest

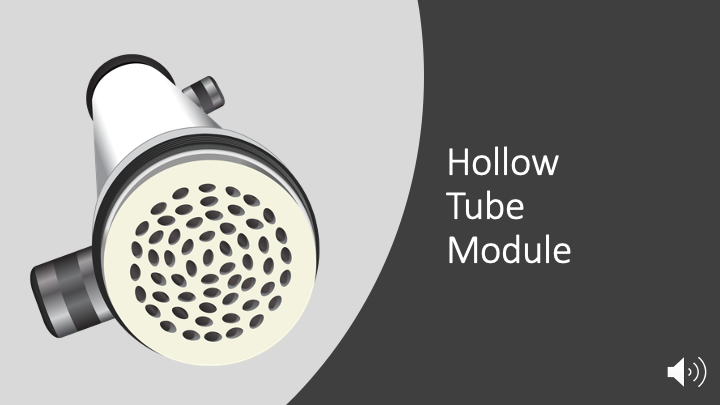

learn more about The Nanocap Process

HVAC Industry

For both residential and commercial applications

Commercial Refrigeration

No more frost formation on the glass panes

Residential Refrigeration

Keep food longer without spoiling

Lumber Drying

Used in conjunction with heating to dry green lumber

Wine Cellar

Allowing precision temperature control

... and more

We can solve a variety of your dehumidification needs